from concept

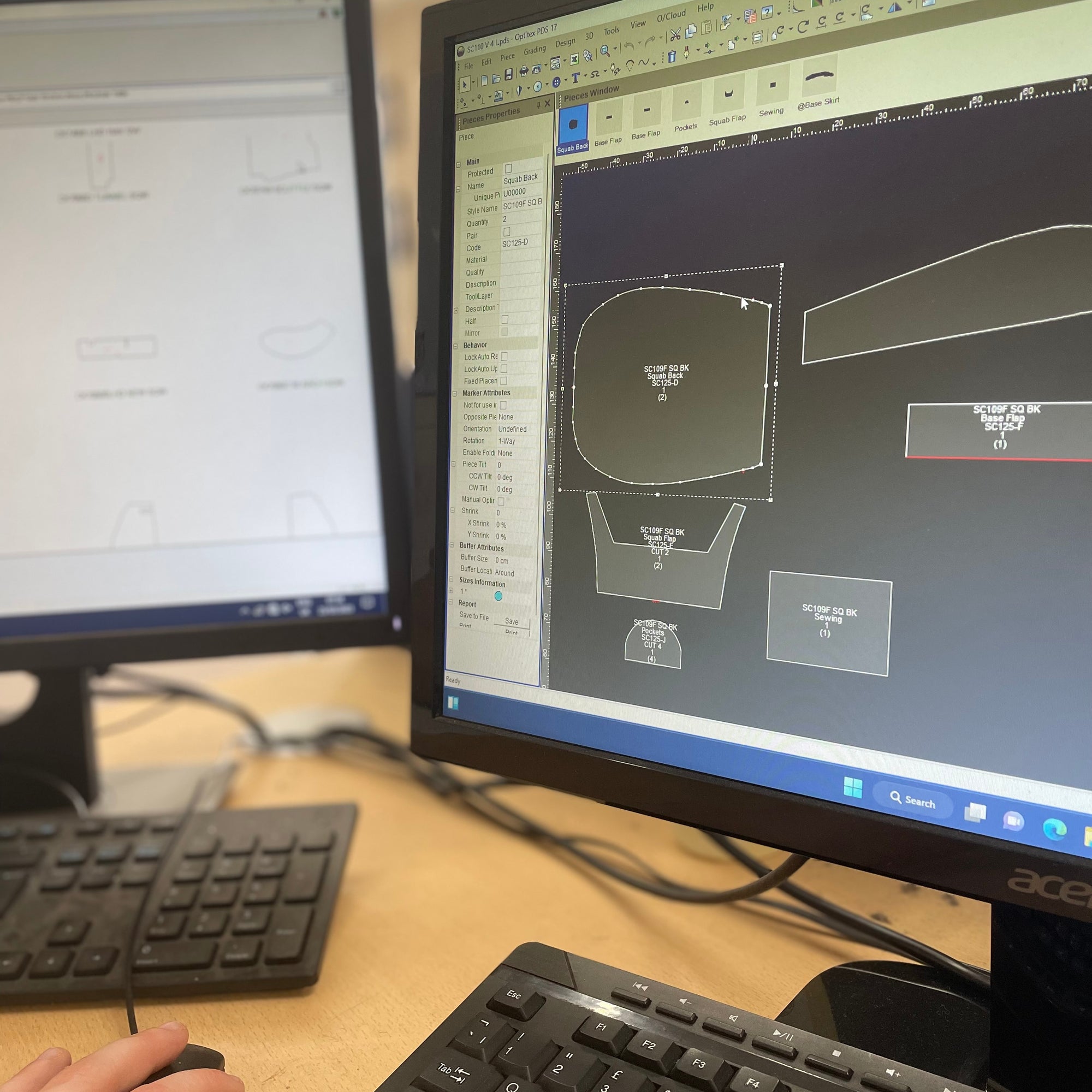

With over 40 years of manufacturing experience, our product development team are well equipped to help with your next project, from initial concept design to problem solving both physically and with CAD prototypes, making your product a reality.

We can help with improved design features and manufacturing techniques to provide a high quality and cost effective solution to help get your product into final production.

Our investment in new technology and manufacturing processes continues to build our catalogue of skills, which we continue to grow over time.

to completion

Joining forces with our product development team is our skilled production team who are able to rapidly turn a concept into a full manufacturing operation.

Once your concept has been tried and tested, the development team will work with our team to ensure a high quality is mainatained throughout all products.

For those with an existing project that you are looking to upscale, our development team can offer a perfect solution to your bespoke manufacturing needs.