Our two Bullmer cutting machines allow us greater flexibility and cutting capacity to support your cut and supply needs. With our CNC cutting machines, there is no maximum cut length - the only limit is available material length, making it easy for us to support you on projects large and small.

Over the years our investment into computer aided cutting machines has allowed us to add more automotive products into our range at greater speed with the continued high level of attention to detail and quality Newton Commercial are renowned for

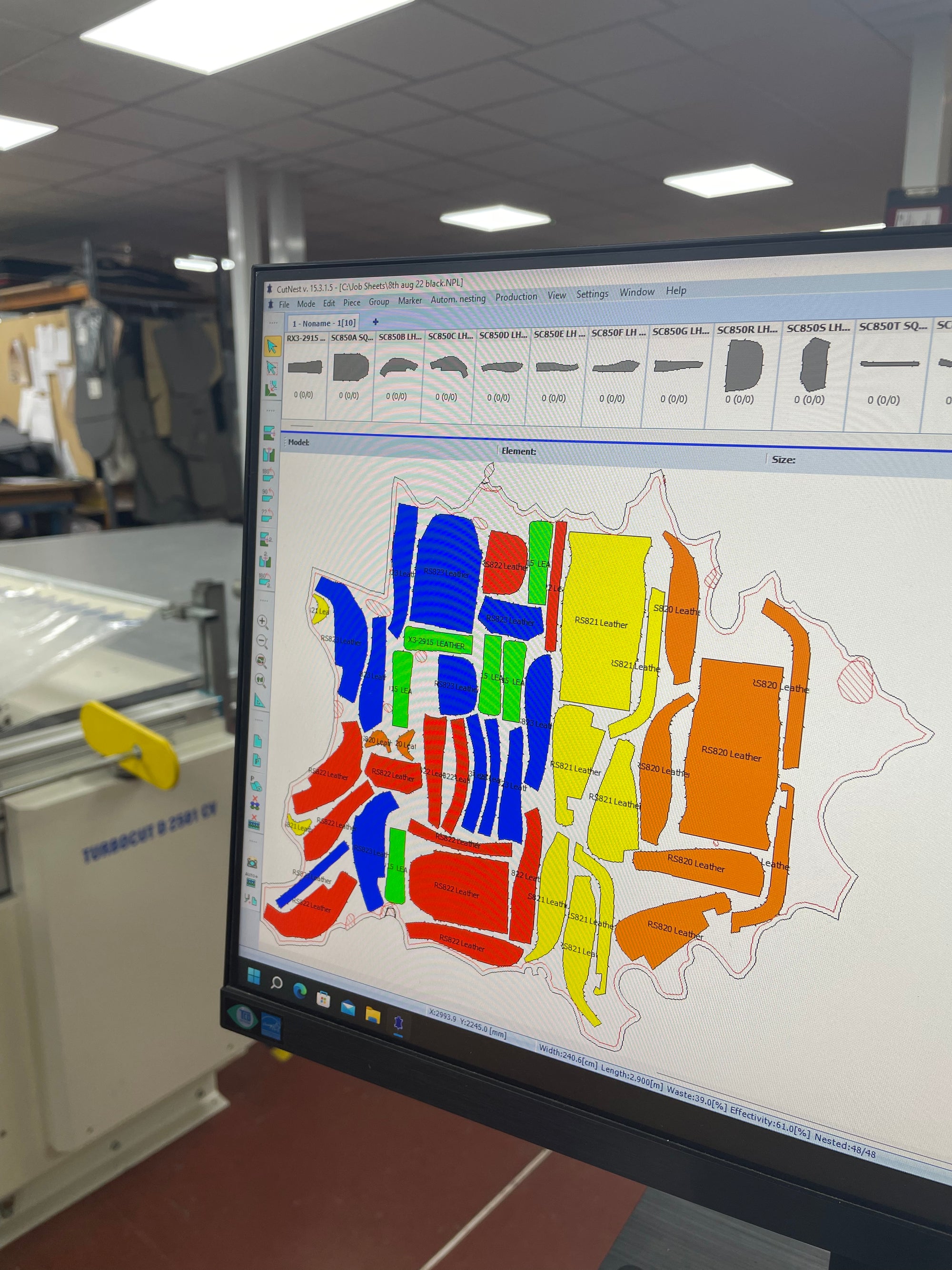

Using state of the art PDS, Marker Maker and Accumark software, our auto nesting feature increase cutting efficiency and creates the optimal cut every time. This allows greater efficiency with less waste, essential to bulk manufacturing a wide variety of products at competitive prices. Leather cutting uses our Mirysis software to make efficient use of leather hides while still allowing us to remove leather flaws that our team of skilled operators mark out every time.

Our Bullmer Turbocut multi lay cutting machine allows us to cut large batches of a variety of products, from panels to headlining, seat covers to carpet.

In 2020 we installed our brand new single ply Bullmer CAD cutting machine. Its most impressive feature is the leather scanning feature which allows us to cut leather hides using state of the art Mirisys software.

Our high quality leather hides are all sourced within the UK and are hand inspected by our team of skilled cutting personnel before any natural flaws or imperfections are marked out