Our original high frequency weld machine was installed in the factory in 1988 has been key to manufacturing a wide range of products including seat covers and door panels over the last three decades. This machine is still used to make a variety of items from sun visors to tool pouches and Lucas lamp covers across a number of our classic car interior trim ranges.

Our new high frequency weld machine allows us to expand our expertise in this field whilst using our original brass tooling created over the last 30 years. This machine features two trays on either side for greater efficiency and is also fully programmable.

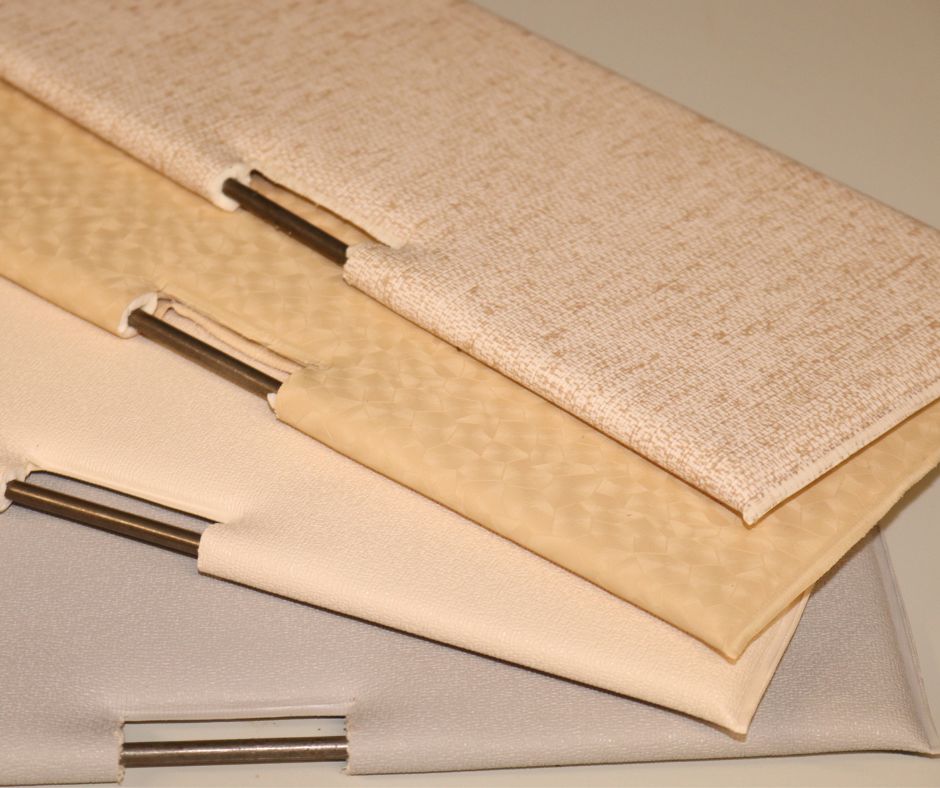

This machine has become a vital part for the running of our UK factory, providing embossed parts to all our departments to use to manufacture your new classic car interior trim.